Objective Visual Evaluation

byko-spectra pro

Product Info

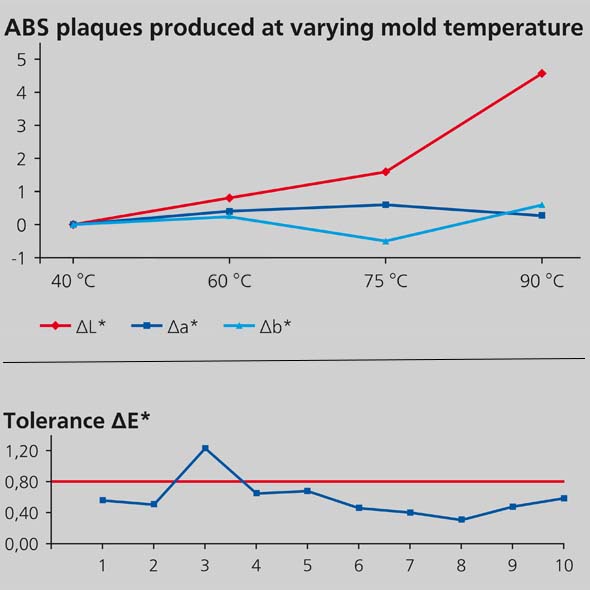

In plastics processing injection molding is the most common method of part manufacturing. The variety of molded parts produced by injection molding extends from smallest components like cell phone buttons up to entire body panels of cars. Plastic moldings are manufactured in production batches of up to several million. In addition to dimensional stability, color and gloss are the decisive quality criteria.

In principle injection molding consists of high pressure injection of the raw material into a mold which shapes the polymer into the desired shape. Initially, plastic material, usually supplied in granular or powder form by the raw material manufacturer, is fed by gravity from a hopper into a heated barrel with a reciprocating screw. As the raw material is moved forward in the heated barrel by the screw, the granules get mixed, homogenize and melt. Following the plasticizing process, the hot molten plastic material is injected through the axial feed of the screw under high pressure into the mold. For thermoplastic materials, the melt needs to be cooled in the mold to ensure the necessary dimensional stability. Once the part is sufficiently cool, the mold opens and the part is ejected.