Testing Solutions for Appearance Control

Gloss meter – Orange Peel meter – Haze meter – Transmission meter – Paint Mottling meter

Orange Peel Measurement at its best

The wave-scan 3 can do everything the old wave-scan was capable plus much more:

- New appearance scales such as “dominant wavelength” analysis, require high computing power. The new wave-scan 3 is equipped with state-of-the-art chip technology to provide measurement results for any scale in 1.2 seconds.

- The new wave-scan 3 shows Pass / Fail of your measurement data directly on the instrument display.

- All is packaged in an ergonomic design with large color touch display for ultimate user friendliness.

Click here to get a firsthand experience of all the new benefits including a short explanation of the measurement principle - presented by our product manager Severin Wimmer.

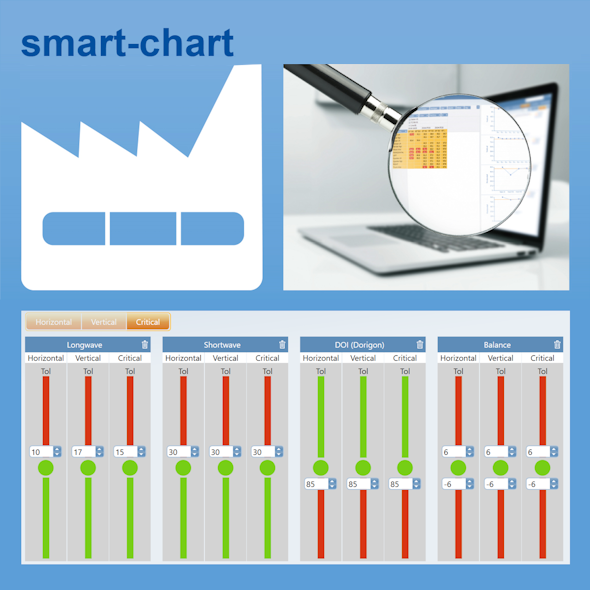

Don’t miss the NEW smart-chart!

More Flexibility for Orange Peel Measurement

For wave-scan, cloud-runner and micro-gloss additional tolerance groups besides Horizontal & Vertical can be defined. The activated tolerance groups are displayed in the single vehicle as well as trend report.

The latest release even offers more new features:

- Automatic check for smart-chart update

- Additional special characters for naming

- New function "Delete all organizers"

Why is the micro-gloss the unsur-passed Industry Standard for Gloss Measurement?

In order to guarantee gloss harmony i.e. no visual gloss differences between adjacent parts coming from different suppliers a glossmeter needs to fulfill the following technical requirements:

- Excellent short and long-term repeatable results

- Temperature stable results - no matter whether you measure inside or outside in winter or in summer time

- Same results from instrument to instrument

- Reliable data at any gloss level for high to low gloss applications

Click here to get insides of the micro-gloss technical performance illustrated with practical examples.

Gloss Measurement of small Parts

Often small parts are integrated in a large part or connect parts such as frames, buttons or decorative trim pieces.

Check out how the micro-gloss XS helps to ensure a harmonized appearance!

Automated Gloss Measurement

Non-contact with 3mm Distance

A stable running process is the key for uniform and consistent quality. With the new micro-gloss robotic automatic appearance control can be performed.

Non-contact measurement allows even faster cycle time, and in addition the product is unaffected by the measurement.

TRADE-IN your old Glossmeter

The micro-gloss is the unsurpassed reference in gloss measure-ment. It is time for you to become a club member to enjoy the following exclusive benefits.

- Technical performance at its best – unmatched by any competitor: Repeatable, reproducible results with guaranteed temperature stable results

- Intelligent gloss measurement: An auto-diagnosis is performed automatically on the gloss standard built into the instrument holder.

- Seamless gloss communication: The smart-chart software saves data, provides professional reports and trend graphing to guarantee process stability.

Special TRADE-IN promotion - 15%: Trade-in other brand glossmeter

GET A QUOTATION GLOSSMETER GUIDE

+++ Valid until December 31, 2024 +++

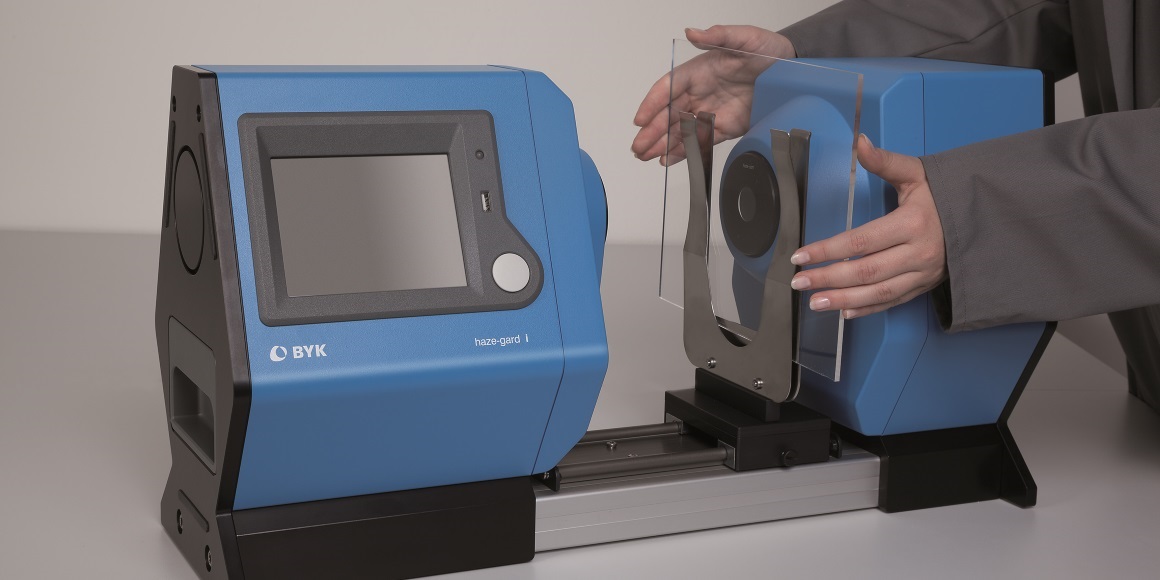

Haze measurement quantifies

SOFT FOCUS effect of lotions

In the cosmetic industry the soft focus effect is used in anti-aging creams and tinted lotions. The idea is to diminish skin imperfections and to create a natural look.

Therefore, the lotion should have a high percentage of total transmission as well as transmission haze.

The haze-gard i is used to objectively evaluate the efficiency of soft focus products.

Transparency Measurement

In order to guarantee consistent color, gloss and transparency of the final product, a routine quality control system needs to be established at the very first production step.

Otherwise, the phrase “garbage in – garbage out” may become reality.

The haze-gard i is used to objectively evaluate the quality of raw materials as well the final product.

Testing Solutions for Color Harmony and Surface Texture

Handheld & Benchtop Spectrophotometer – Light Booths – Liquid Color Meter

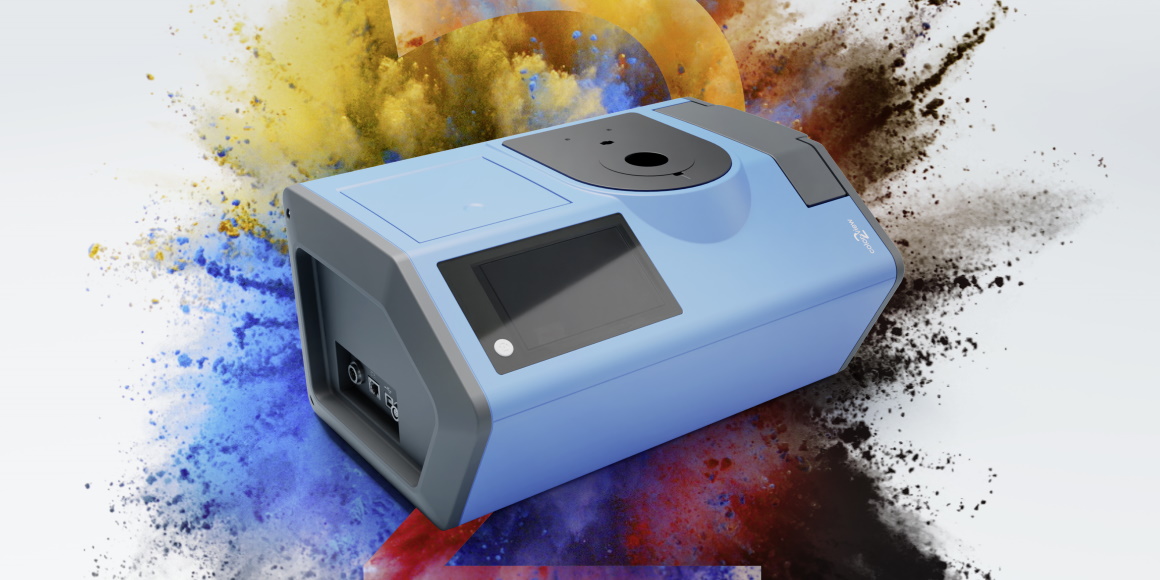

The “Revolution in Color Measurement” continues

Color quality control of small parts made easy with the new spectro2go XS

The visual impression defines our judgment of quality and is the key driver in our purchasing decision. Color uniformity, also referred to as “COLOR HARMONY”, is especially important for multi-component products. Small parts can easily stand out like a thorn in the side, if their color does not match the other components.

WELCOME the new spectro2go XS

New color spectrophotometer for measurement of small parts

Turning old into new: Investing in the future!

The possibilities offered by new technologies today were hardly imaginable a few years ago. The new spectro2guide lives up to its slogan "The revolution in color measurement".

A repair or recertification of our first generation of color meters, spectro-guide family, can no longer be guaranteed due to unavailability of spare parts (manufactured before 2013). Another reason to retire a 10 year old device and take advantage of this unique TRADE-IN offer.

15% Discount: Trade-in your spectro-guide or other brand color instruments

+++ Valid until September 30, 2024 +++

Become a smart-lab professional - free of charge!

How are color standards created?

Where are color tolerances defined?

How do I measure color online or offline?

How are color measurement results analyzed?

How can color results be shared?

The new step-by-step guide for smart-lab with spectro2guide shows in detail how to easily use the software smart-lab, divided into small tasks.

Become a smart-process professional - free of charge!

Systematic planning and efficient data handling of large data sets is essential to set-up a global QC management system for effect finishes.

Get to know all smart-process tools that make the world of data analysis transparent, easy to interpret and efficient - in one comprehensive guide.

No Surprising Mismatches! A Light Booth offers Standardized Conditions

It is a real challenge to achieve standard daylight D65 as defined by CIE. The light booth byko-spectra pro uses a smart combination of filtered tungsten-halogen lamps and LEDs to achieve best possible agreement with natural daylight.

- Highest rendering Class A according to CIE 51.2 - unsurpassed in the industry.

- Actual color temperature, light intensity and lamp operation time are displayed

to trigger lamp replacement. - Auto sequence mode allows focusing on color appraisal only.

See things the right way with byko-spectra pro!

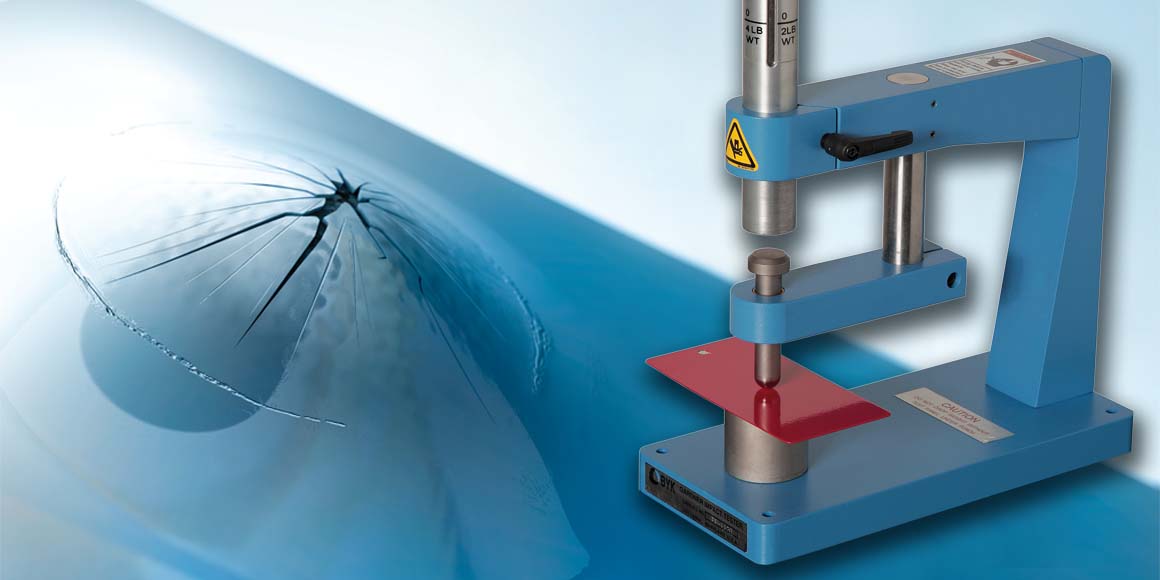

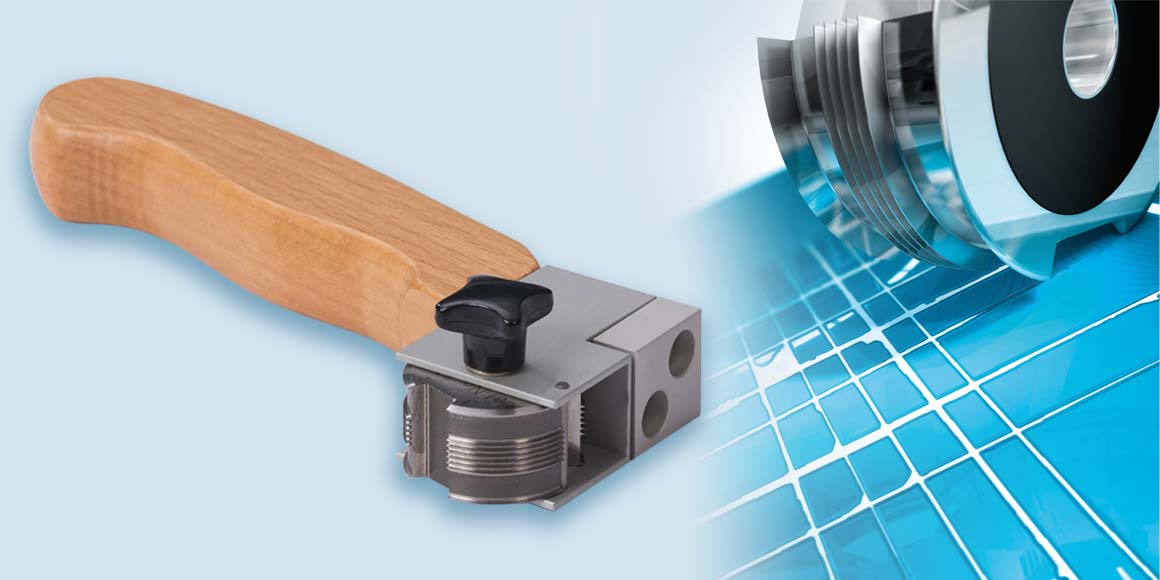

Testing Physical Properties of Paints & Plastics

From wet to dry: Abrasion Test – Adhesion Test – Coating Thickness Gauge – Hardness Tester – Impact Test – Paint Application – Viscometer

NEW Lauda Loop L100

BYK-Gardner now offers this advanced thermoelectric circulator with innovative Peltier technology. It allows for precise control of the temperature in a compact and efficient way. It is the ideal temperature control solution for our byko-visc RT small sample and low viscosity adapters.

- Innovative, refrigerant free Peltier technology

- Compact and quiet

- Fast and precise thermostating capabilites

- User friendly OLED display

byko-test 9500: Precise and Accurate Dry Film Thickness Measurements

The byko-test 9500 dry film thickness gauge is the perfect tool for a wide range of applications. It is compatible with ferrous as well as non-ferrous substrates on smooth, rough, and even curved surfaces. A scratch and chemical resistant display with dust and splash water protection make it the ideal workhorse for everyday measurements.

- Easy to use operator menu

- Temperature compensation directly in the sensor

- Precise measurements even on curvatures and small parts

- Simple and fast creation of documentation and reports

byko-visc CP: Rotate and Flow through Thick and Thin

The byko-visc Cone and Plate viscometer allows for the precise determination of the absolute viscosity of materials using minimal sample sizes. With built-in temperature control and constant shear rates throughout the whole sample it can measure and predict the performance of your samples closer to the conditions in your manufacturing or application process.

- Precise shear rates from a robust direct drive motor

- Built in temperature control

- Automatic electronic cone lift

- Small sample sizes save both material and clean time

- Precise data from instrument-to-instrument & day-to-day

- Intuitive navigation on a large color touch display

NEW byko-visc RT: Rotate and Flow through Thick and Thin

Viscosity is an important material property which needs to be specified and controlled to optimize how a liquid flows, spreads, or levels under certain conditions. The byko-visc RT is available as a standard and lite version with models for low, medium or high sensitivity to cover a wide range of applications and versatility in data analysis.

- Robust design with adjustable stand

- Easy snap-on spindle attachment

- Solvent resistant housing

- Precise data from instrument-to-instrument & day-to-day

- Intuitive navigation on a large color touch display

- Ready right out of the box - no assembly needed!

byko-charts Drawdown Cards Eliminate False Paint Rejects

BYK-Gardner offers a wide range of drawdown cards for virtually any material. Typical applications are opacity check, evaluation of spreading rate, paint penetration and flow/leveling behaviour. The test cards are used as substrate for architectural, industrial, automotive, wood finishes or even cosmetic products. Depending on the coating properties film laminated test cards, ideal for solventborne formulations or clearcoated test cards, are available. BYK-Gardner goes to great lengths to test, monitor and keep records of byko-charts to ensure the cards have consistent color and gloss from print batch to print batch.

Why is this important?

Variations in gloss as well as color on test cards can cause erroneous rejection of paint batches - most important for non-opaque finishes.

Do you always have the right tool at hand to measure film thickness?

Film Thickness and Dew Point in one tool in accordance with SSPC-PA2: byko-test

The 4-in-1 byko-test measures film thickness on Fe/NFe substrates plus humidity, temperature and dew point with high precision. Ideal for coaters of exterior structures, like marine or protective applications.

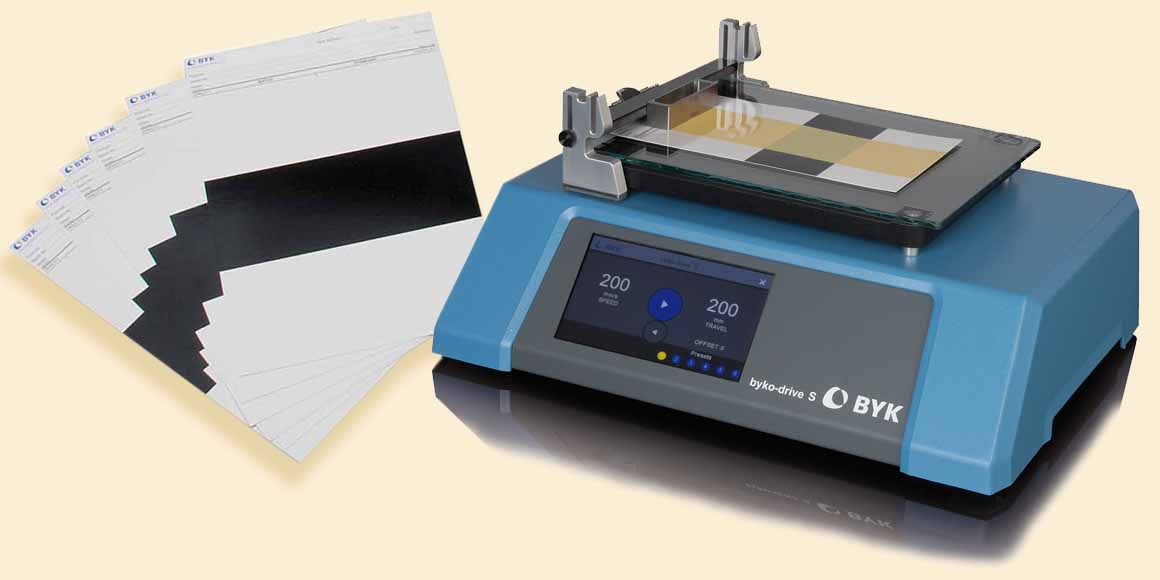

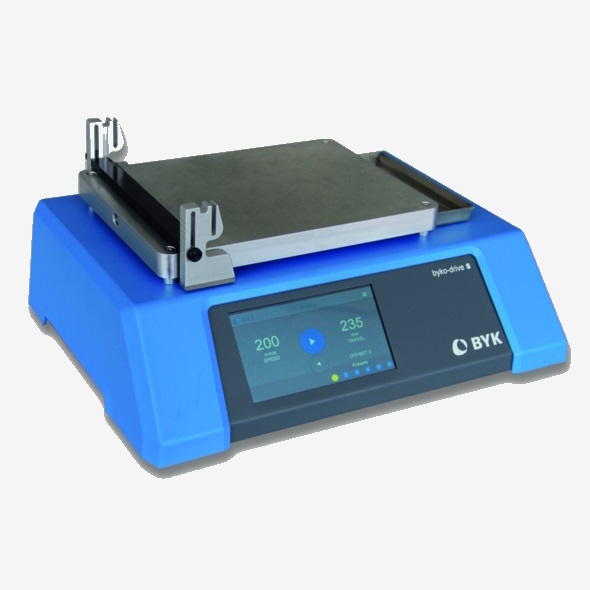

byko-drive S:

Paint Application Automated

The byko-drive S is an automatic film applicator for consistent drawdowns with user selectable speeds 0 - 200 mm/s, with a glass plate plus clamp or a vaccum plate to fix a variety of substrates.

- User selectable start and stop positions to accommodate different size charts

- Small footprint to save on counter space

- Drip pan for faster cleanup

- Easy to operate user controls

The byko-drive S is designed to assist the user in achieving consistent film application by maintaining a consistent speed and drawdown pressure.

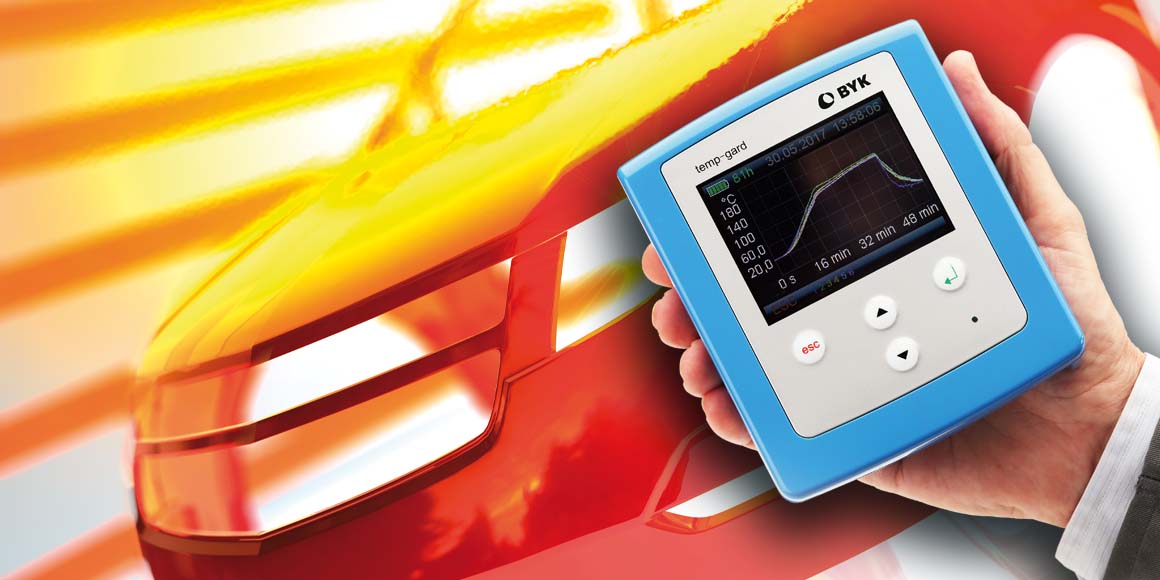

Temperature Data Logger Docu-

ments & Optimizes Your Curing Temperature

Is the paint cured at all points of the product?

Ideal cure time and temperature are a hot topic to save energy and money. The BYK-Gardner temp-gard, a high quality temperature data logger offers temperature data storage for six up to twelve temperature sensors.

The temp-chart software shows the temperature profile and analyzes the data based on maximum and peak temperatures. The Cure Index is a fast Pass/Fail method to determine cure status. Combined with Cure Chart analysis line speed and temperature can be optimized.

Letter of Conformance

We offer a Letter of Conformance for all physical test products without certificates. It references international standards, which the product is in compliance. Thus, you can be assured of the high quality of your testing tool.

SSPC recommends to check environmental conditions prior to painting!

We provide a field testing kit for protective coatings in accordance with SSPC PA-2:

- Dry Film Thickness Measurement

- Relative Humidity

- Air and Surface Temperature

- Dew Point

- Wind Speed and Air Velocity

- Moisture content of porous substrates

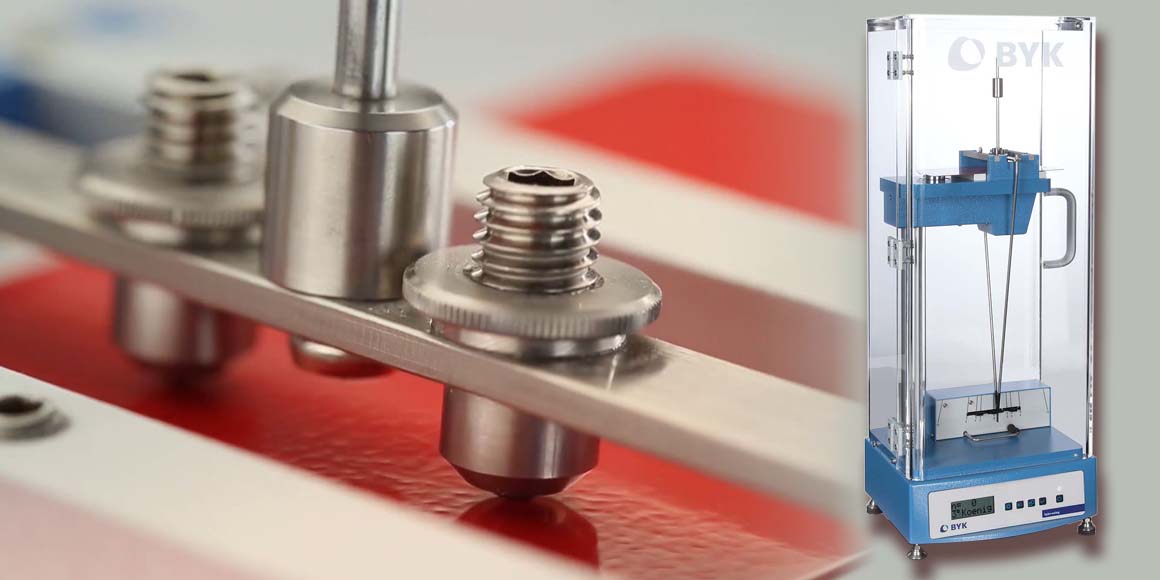

NEW byko-swing:

Pendulum Hardness Tester with Automated Test Procedure

This test method evaluates the elasticity of a coating by measuring the damping time of an oscillating pendulum. The shorter the damping time, the higher the flexibility.

The new byko-swing has automated this test procedure to guarantee reliable readings and to save valuable time.

- Motorized sample platform lifts the sample into the test position

- Automatic positioning and release of pendulum

- Automatic counter with signal when test is finished

Non-Destructive Testing Solutions with Ultrasound

Pulser, Receivers – Transducers – Multi-Layer Film Thickness Gauge

Film Thickness Gauge for any substrate

PELT film thickness gauge provides a non-destructive measurement solution for multi-layer film thicknesses – all within a single measurement.

PELT film thickness gauges are essentially acoustic microscopes. Very high frequency ultra-short pulses of ultrasound are used to resolve and measure layer coating thickness – even as thin as 5 µm. The technology works on a wide variety of substrates – with highest accuracy: Steel - Carbon Fiber - Aluminum - Rubber - Composites - Glass - Plastics - Wood.

With PELT, there is no need to change transducers for different substrate materials.

A wide range of transducers allows multi-layer film thickness measurement for Thin – Thick Film Layers.

Film Thickness Gauge for any substrate

PELT film thickness gauge provides a non-destructive measurement solution for multi-layer film thicknesses – all within a single measurement.

PELT film thickness gauges are essentially acoustic microscopes. Very high frequency ultra-short pulses of ultrasound are used to resolve and measure layer coating thickness – even as thin as 5 µm. The technology works on a wide variety of substrates – with highest accuracy: Steel - Carbon Fiber - Aluminum - Rubber - Composites - Glass - Plastics - Wood.

With PELT, there is no need to change transducers for different substrate materials.

A wide range of transducers allows multi-layer film thickness measurement for Thin – Thick Film Layers.

Handheld Paint Thickness Gauge for Multi-Layer Measurement

PELT gauges provide a non-destructive solution for measuring multi-layer film thicknesses with a single measurement on a wide variety of substrates.

Very high frequency ultra-short pulses of ultrasound are used to resolve and measure layer coating thickness. Innovative high frequency transducer technology combined with unique high frequency pulser / receivers guarantee an outstanding technical performance:

- Resolution: 0.5 - 0.33 µm (0.02 - 0.013 mils)

- Calibrated Accuracy: ± 1.3 µm (+/- 0.05 mils) or ± 2% of the coating thickness, whichever is greater

Transducers for a wide range of thickness and materials

We have developed novel fabrication techniques to manufacture, bond and assemble very high frequency elements with an unsurpassed precision, reliability and long service life:

- Low frequency transducers for thick layers up to 5 mm

- Medium frequency transducers for layers 18 - 500 µm

- High frequency transducers for thin layers down to 5 µm

Latest transducer technology is used in Generation II (‘B’ suffix) offering higher sensitivity and resolving power than Generation I. The higher sensitivity enables improvements in the ability to discern lower contrasting layers and the higher resolving power facilitates gauging of thinner layers.

Automated Paint Film Thickness Measurements

Only an automated measurement solution allows adequate sampling of the paint production process for multiple body styles, paint lines, and colors.

- The PELT End-of-Arm-Tool (EOAT) provides compliance to body surfaces. There is no sensitivity to vibration.

- Outstanding technical performance with 0.5 µm resolution.

- Measurement of coating thickness as thin as 5 µm

- smart-chart chart software gathers all measurement data in one database for SPC analysis

- BYK-PELT ROBOTIC can be mounted on the same robot together with wave-scan ROBOTIC and BYK-mac i ROBOTIC.

READY FOR INDUSTRY 4.0