When being used for furniture, wood coatings have to fulfill two main requirements: they have to guarantee durability and resistance against a variety of household chemicals and solvents, but at the same time the product has to look nice and esthetically appealing.

Depending on the exclusivity of the furniture, different “types” of wood are used. High-end furniture is made out of natural solid wood or veneer, whereas inexpensive products are made of plywood. Solid wood is usually covered with a clear or tinted stain that is applied in different ways determined by the geometry of the part. Flat parts like boards and cabinet doors are coated by rolling or flowing when being processed by a flat conveyor line. More complicated shaped parts like chairs or complete furniture pieces are hung on carriers and sprayed. Plywood can either be coated with an opaque solid coating or laminated with a thin paper film of different design ranging from solids to wood grain imitations.

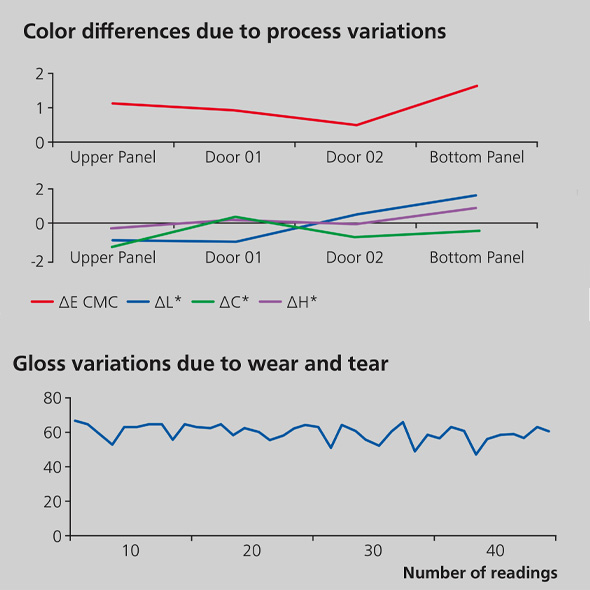

As design decisions are often made at different locations than manufacturing takes place and parts from different suppliers worldwide are assembled to the finished product, a reliable color and gloss control is crucial. A color instrument using a sphere (d/8), specular-included geometry is best suited to measure color variations on wooden surfaces. Depending on the gloss level of the sample, either a 60° or 20° gloss measurement is recommended additionally.